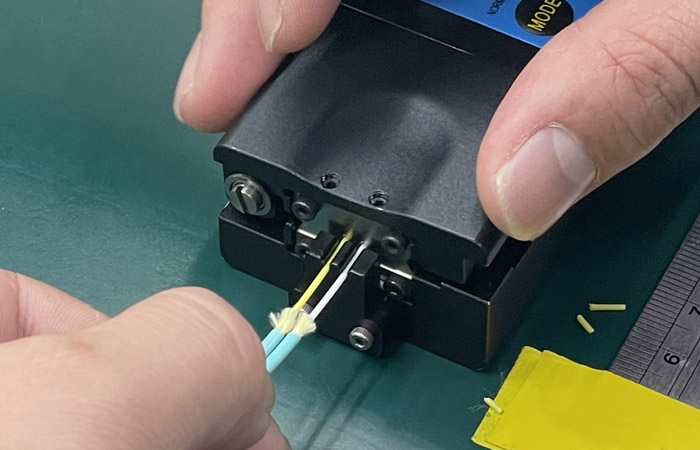

Termination

Measured and stripped to spec with accuracy

Epoxy cured with consistency

Polishing

24 fibers are machine polished at once to achieve precision geometry

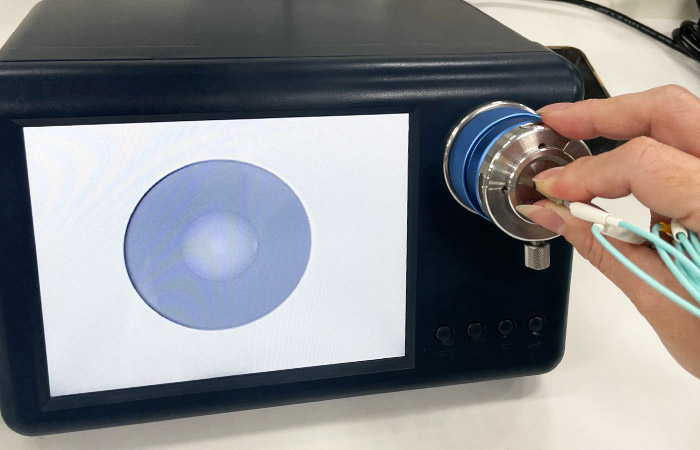

Finishing

End-face inspected for contaminants

Testing

3-D metrology tested measuring the orientation of the strain elements

Insertion loss and return loss tested

Bezel Assembly

Adapters snapped into bezels, mounting clips reduce movement

Pre-terminated and pre-tested patch cables are ordered in sequence

Bundling

Durable cable bundling

Labeling

Self-laminated adhesive labels

Helps in identifying cables and bundles

Final Testing

Final verification before shipping

Packaging

Bezels bubble wrapped

Twist tied cable assembly

Bagged, labeled, and boxed